DIY Closet Shelves: Egger Laminated Chipboard + 3D-Printed Shelf Pins (5.8 mm) on a Prusa MK3S+

Disclaimer: all companies and brands mentioned below (Viyar, Egger, REHAU, Prusa, Tinkercad, Dnipro-M, etc.) are not sponsors.

Regional note: some of these are Ukrainian brands / Ukrainian suppliers (pricing, availability, and naming may be local).

I wanted better closet shelves for my 9-month-old’s clothes. Getting shelves cut from laminated chipboard is easy, but shelf hardware is where small annoyances start: wrong size, store trips, shipping, and then it still doesn’t fit perfectly.

So I did it the “engineer at home” way: chipboard shelves via a cutting service, and shelf pins (shelf pegs) 3D-printed at home. Fast, minimal hassle, and the whole thing came out at about ~900 UAH.

Photos: order + manager response

What I did

- 3D-printed shelf pins (shelf pegs) in PLA, ~5.8 mm

- Ordered custom chipboard cutting (and edgebanding) from a Ukrainian supplier

- Drilled holes in the closet niche (I’m not a pro woodworker — just careful)

- Assembled shelves for light loads (kids’ clothing)

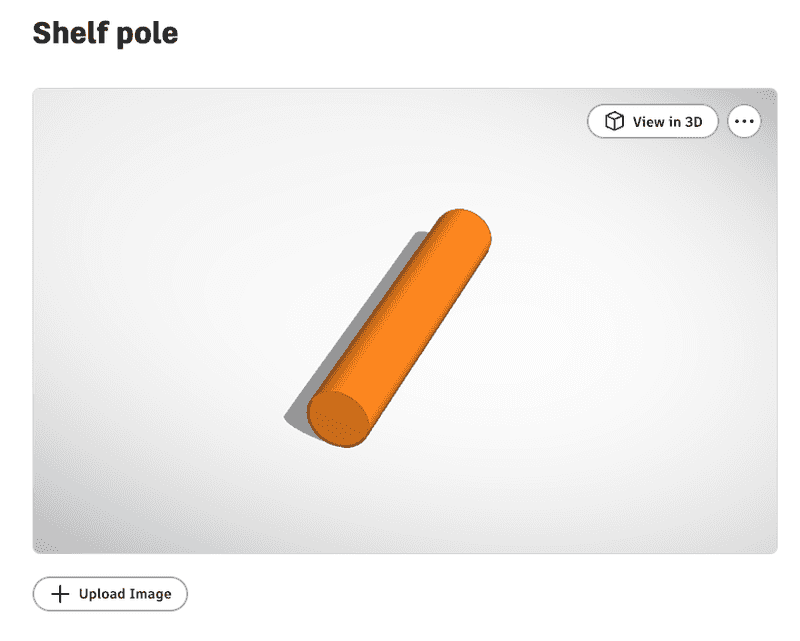

3D-printed shelf pins: model, material, fit

I modeled a super simple part (basically a small cylinder pin) in Tinkercad.

- Tinkercad screenshot:

- Project: https://www.tinkercad.com/things/6tVoel3IrcA-shelf-pole

- Printer: Prusa MK3S+

- Material: PLA

- Pin diameter: ~5.8 mm

- Hole size: 5.5 mm

Why 5.8 mm in a 5.5 mm hole?

That’s an interference fit: I wanted the pin to hold firmly without glue and without wobble.

Important: “how tight” this fit is depends on:

- printer calibration (real outer diameter),

- PLA behavior,

- drill bit accuracy + the material you drill into.

Practical tip: print one test pin first and try it in one hole before doing everything at scale.

Ordering the shelves: laminated chipboard cutting + edgebanding

My shelf size was 586 × 487 mm, 3 pieces.

Specs I used (for reference):

- Laminated chipboard: Egger U961 Black Graphite ST7, 18 mm

- Edgebanding: only the front edge (586 mm) per shelf

- Edge band: ABS 23×1 mm, black graphite, REHAU (matte)

- Pickup: self pickup

What I liked: they replied with a quote the same day by email — genuinely fast.

Drilling holes in the niche (I’m not a pro)

I kept it simple:

- Marked the shelf height.

- Marked 4 pin locations (2 per side).

- Drilled with a 5.5 mm bit.

What I’d improve next time:

- Make a basic drilling jig/template (even a scrap strip) so all holes line up perfectly.

- Add a depth stop (tape on the bit works) to avoid going deeper than needed.

Installing the shelves

No magic:

- insert pins,

- place the shelf board,

- check for level + wobble.

Since this is for kids’ clothes, the load is light, and PLA pins are totally fine here. For heavy loads (books/tools), I’d use metal pins or redesign the support geometry/material.

Result (installed shelves)

And here’s how it looked right after drilling (dust included — real DIY):

Tools & process

Cost

Total: about ~900 UAH (chipboard + cutting/edgebanding + small bits).

Yes, I could have bought shelf pins. But in practice:

- Tinkercad + Prusa MK3S+ + ~1 hour = parts in hand

- no trips, no shipping, and a perfect size for my niche

FAQ

Will PLA shelf pins hold up?

For light loads like clothes — yes. For heavy stuff, use metal pins or rethink the design.

What pin diameter should I print?

Start with a test. My setup worked as ~5.8 mm pin in a 5.5 mm hole, but your printer/material/drill accuracy may differ.

What should I use to drill the holes?

I used a drill/driver and a 5.5 mm bit. The biggest win is careful marking; a simple jig makes it almost foolproof.

P.S. (optional)

If you also 3D-print small practical parts at home, I occasionally post short DIY notes like this in my blog.